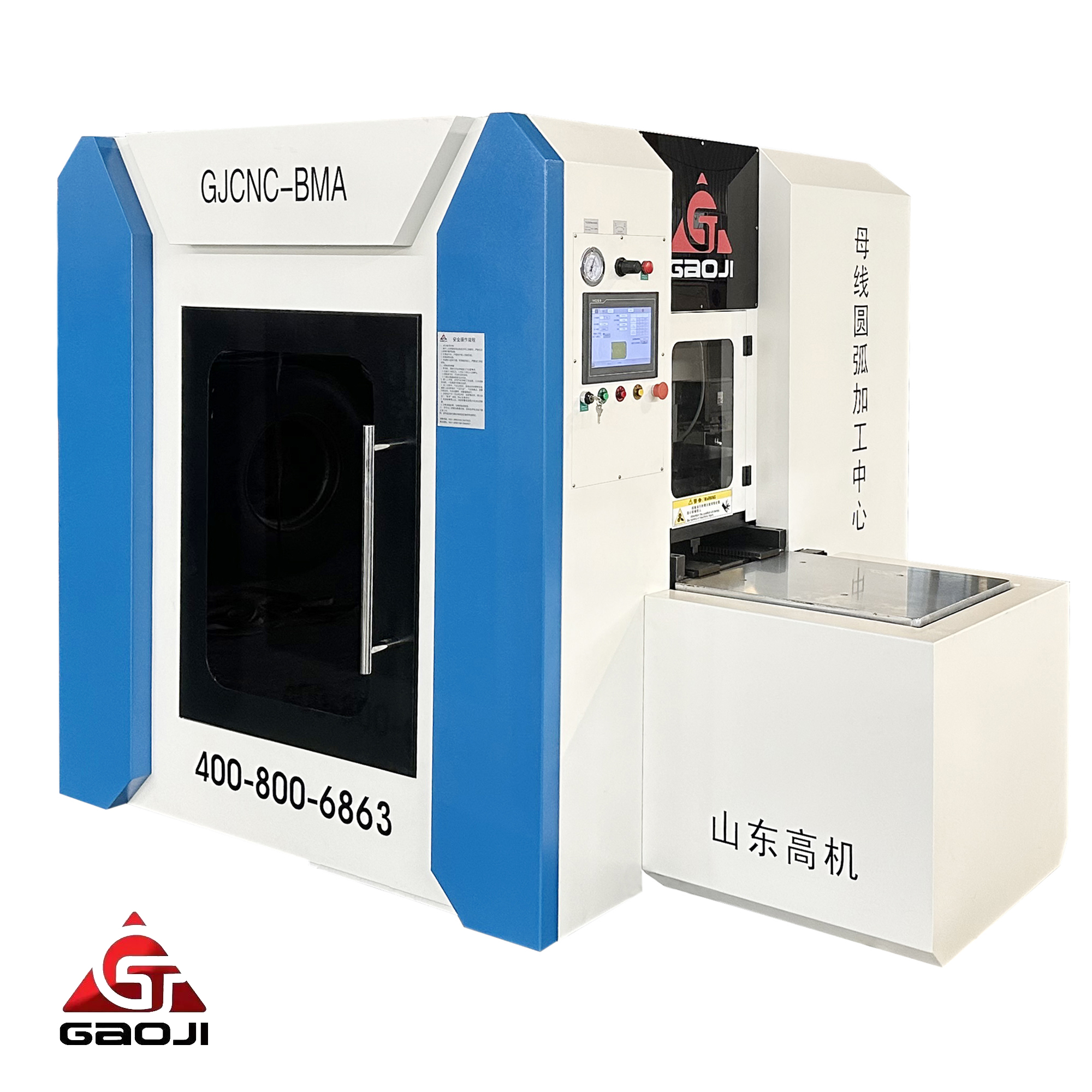

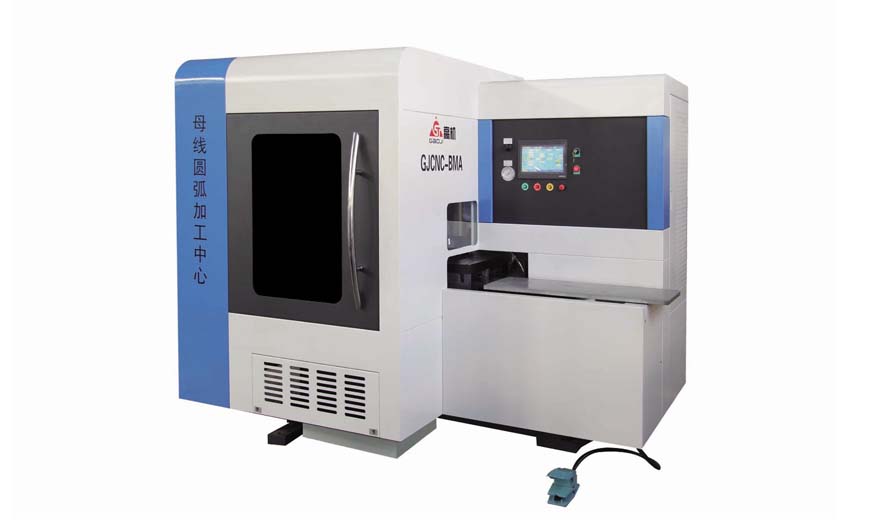

Emptio Super pro centro machinationis BUS Arc (Machina Chamfering)

Clientes nostros honoratos plerumque satisfacimus qualitate optima, pretio praestanti, et auxilio optimo, quia multo peritiores et diligentiores fuimus, et id modo sumptuum efficaci facimus pro Super Emptione pro Centro Machinationis Arcus BUS (Machina Chamfering). In futurum prospicientes, longa via est adhuc peragenda, constanter contendentes ut omnes operarii cum pleno studio, centuplo fiducia, et societatem nostram aedificasse pulchrum ambitum, producta provecta, qualitatem primae classis, modernam societatem, et laborem strenuum ponentes!

Clientes nostros honoratos plerumque satisfacimus optima qualitate, pretio praestanti, et auxilio optimo, quia multo peritiores et diligentiores fuimus, idque modo minoris sumptus facimus. Ut plura de nobis cognoscas et omnia producta et solutiones nostras videas, locum nostrum interretialem visitare debes. Ut plura cognoscas, libenter nobiscum certiores facias. Gratias tibi ago maximas et optamus ut negotium tuum semper optimum sit!

Singula Producti

Machina CNC ad vectes communes fresandas praecipue in fresando angulis et angulis magnis in vecte communi fungitur. Automate codicem programmatis generat et codicem ad apparatum transmittit, secundum requisita specificationis vectis communis et data in screen ingressa. Facile operatur et arcum utilem vectis communis cum aspectu pulchro fabricare potest.

Commodum

Haec machina ad perficiendam arcum sectionalem pro capitibus virgarum omnibus (busbar) cum A ≤ 3-15mm, latitudine ≤ 140mm et Longitudine ≥ 280mm adhibetur.

Caput vectis ad formam cum structura fixa machinabitur.

Fibulae technologiam centrationis automaticae adoptant ut caput premens melius in punctum vim portantem premant.

Amplificator in capite prementi adhibetur ad stabilitatem materiae fabricandae confirmandam, effectum superficiei machinationis meliorem praebens.

Instrumentorum tenens BT40 norma mundialis ad facilem laminae commutationem, subtilem rigiditatem et magnam praecisionem adhibetur.

Haec machina cochleas globulares summae praecisionis et ductores lineares adhibet. Ductores magni magnitudinis et oneris gravibus delecti sunt ut rigiditatem totius machinae meliorem praebeant, vibrationem et strepitum minuant, qualitatem operis augeant, et accuratiam atque efficientiam magnam curent.

Utentibus componentibus notarum domesticarum et toto orbe terrarum clararum, haec machina diuturna est et qualitatem summam praestare potest.

Programma in hac machina adhibitum est programmatura graphica automatica inclusa, a societate nostra elaborata, quae automationem in programmatione efficit. Operatori non necesse est varios codices intellegere, nec scire quomodo centrum machinationis traditionale operari. Operatori tantum aliquot parametros inserere debet, ad graphica referendo, et apparatus codices machinae automatice generabit. Brevius tempus quam programmatio manualis requirit et periculum erroris codicis, qui a programmatione manuali oritur, eliminat.

Vectis omnibus in hac machina machinata aspectu elegans est, sine exoneratione punctuali, magnitudinem armarii angustans ad spatium conservandum et consumptionem aeris insigniter reducens.

Clientes nostros honoratos plerumque satisfacimus qualitate optima, pretio praestanti, et auxilio optimo, quia multo peritiores et diligentiores fuimus, et id modo sumptuum efficaci facimus pro Super Emptione pro Centro Machinationis Arcus BUS (Machina Chamfering). In futurum prospicientes, longa via est adhuc peragenda, constanter contendentes ut omnes operarii cum pleno studio, centuplo fiducia, et societatem nostram aedificasse pulchrum ambitum, producta provecta, qualitatem primae classis, modernam societatem, et laborem strenuum ponentes!

Emptiones optimae pro, Ut plura de nobis cognoscas, necnon omnia producta et solutiones nostras videas, paginam nostram interretialem visitare debes. Ut plura cognoscas, libenter nobis nuntia. Gratias tibi ago maximas et optamus ut negotium tuum semper optimum sit!

Configuratio

| Dimensiones (mm) | Pondus (kg) | Magnitudo Mensae Operariae (mm) | Fons Aeris (Mpa) | Potentia Totalis (kW) |

| 2500*2000 | 3300 | 350*900 | 0.5~0.9 | 11.5 |

Parametri Technici

| Potentia Motoris (kW) | 7.5 | Potentia Servo (kW) | 2*1.3 | Torque Maximus (Nm) | 62 |

| Modelus Tenaculi Instrumenti | BT40 | Diameter Instrumenti (mm) | centum | Celeritas Fusi (RPM) | mille |

| Latitudo Materialis (mm) | XXX~CXL | Longitudo Minima Materialis (mm) | 110 | Crassitudo Materialis (mm) | III~XV |

| Spatium Axis X (mm) | 250 | Axis Y Spatium (mm) | 350 | Celeritas Positionis Celeris (mm/min) | 1500 |

| Spatium Cochleae Globulosae (mm) | 10 | Accuratio Positionis (mm) | 0.03 | Celeritas Pascendi (mm/min) | 1200 |